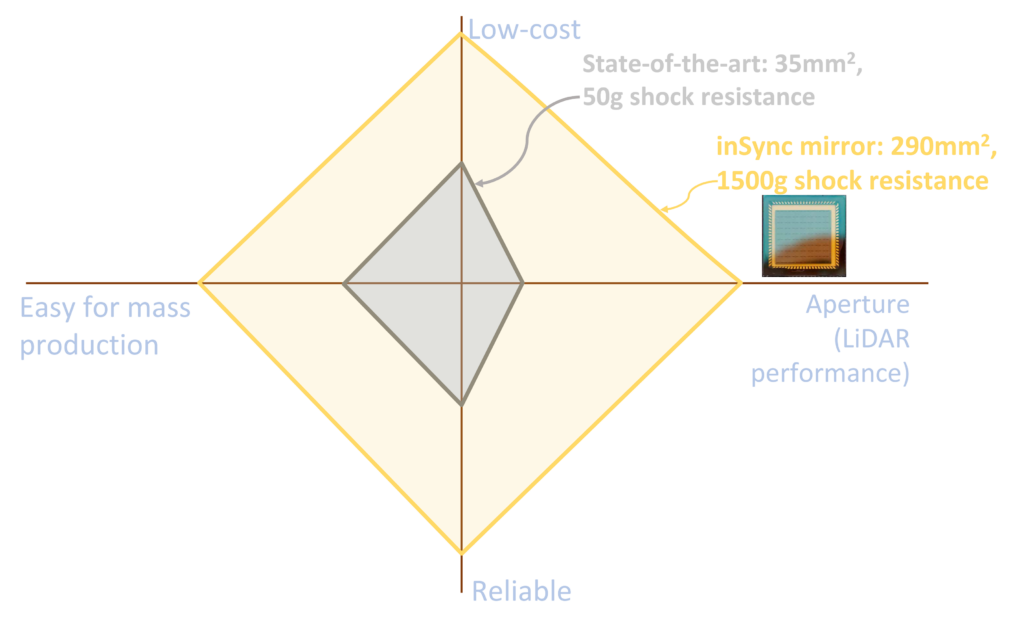

ISM — Large‑Aperture Resonant MEMS Scanners (LiDAR & General Scanning)

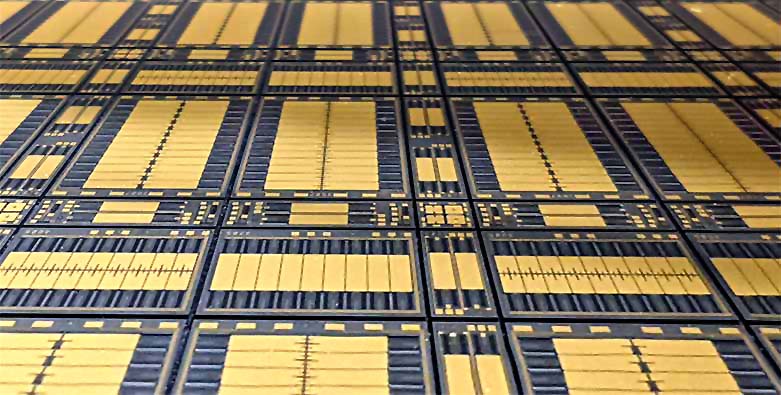

ISM is our resonant, large‑aperture MEMS scanner family for LiDAR and other optical scanning. Instead of one large monolithic mirror, multiple small mirrors are synchronized so they behave like a single, large optical aperture — delivering brightness potential and robustness without the fragility penalties of a big single mirror.

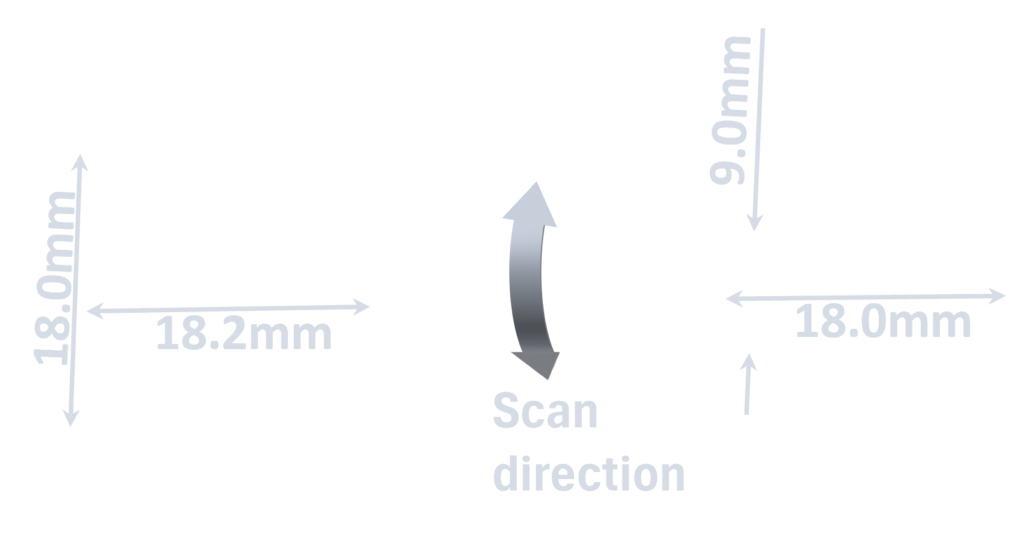

Two aperture options and both 1D and hybrid‑2D scanning are available.

1D Scanner – Effective aperture 290mm2

Max optical scanning angle 20°@2kHz

1D Scanner – Effective aperture 150mm2

Max optical scanning angle 30°@2kHz

2D Scanner – Effective aperture 290mm2

Max optical scanning angle 80°(H)×20°(V)

2D Scanner – Effective aperture 150mm2

Max optical scanning angle 120°(H)×30°(V)

Why ISM is perfect for LiDAR

From the MEMS side

Array architecture increases effective optical aperture without enlarging any single mirror element.

Smaller mirrors keep rotational inertia low, enabling high frequency operation with stable scan geometry.

Multiple hinges and anchors create many heat paths to the substrate, improving thermal handling at higher optical power.

Synchronized equal‑angle motion across elements maintains uniformity and simplifies control and calibration.

From the LiDAR side

Larger effective aperture enables tighter beam collimation and lower TX laser divergence for greater range and resolution.

A larger collecting area improves return‑light capture on RX, boosting link budget and SNR in challenging environments.

High frequency, stable scanning supports dense line counts and precise timing for time‑of‑flight processing.

Robust mechanics and thermal design help maintain performance under vibration, shock, and temperature swings.

Reliability

Thanks to our synchronized small‑element array architecture, ISM devices are extremely reliable. We validate performance against automotive‑style environmental and mechanical standards. For the representative test menu and results, see the Reliability section in Technology page.

Key parameters (ISM150 / ISM290)

ISM 1D (ISM150 / ISM290)

| Parameter | Condition / Notes | ISM150 (Min / Typ / Max) | ISM290 (Min / Typ / Max) | Unit |

|---|---|---|---|---|

| Optical effective aperture | Illuminated area | — / 150 / — | — / 290 / — | mm² |

| Optical scanning angle | Optical, p‑p | — / 25 / 30 | — / 15 / 20 | ° |

| Optical divergence | Reflected beam, collimated input, λ = 905 nm | — / 1 / 2 | — / 1 / 2 | mrad |

| Resonant frequency | Resonant operation | 1900 / 2000 / 2200 | 1900 / 2000 / 2200 | Hz |

| Power consumption | At typical optical angle | 0.4 / 0.5 / 0.7 | 0.6 / 0.75 / 0.9 | mW |

| Drive voltage (Vpp) | Sinusoid, at typical angle | 100 / 125 / 160 | 65 / 70 / 75 | V |

| Drive current | At typical optical angle | 200 / 250 / 300 | 340 / 350 / 380 | µA |

| Mechanical Q | 1 atm | 80 / 100 / 110 | 55 / 60 / 65 | — |

| Angle detection noise | RMS optical angle | — / 0.002 / — | — / 0.002 / — | ° |

| Angle detection accuracy | −40 ~ 85 °C | — / 0.01 / 0.05 | — / 0.01 / 0.05 | ° |

| Mirror reflectivity | 905–1550 nm | 96 / 97 / — | 96 / 97 / — | % |

| G‑shock resistance | Half‑sine, 0.5 ms, 3‑axis, 3× each | 1500 / 3000 / — | 1500 / 3000 / — | g |

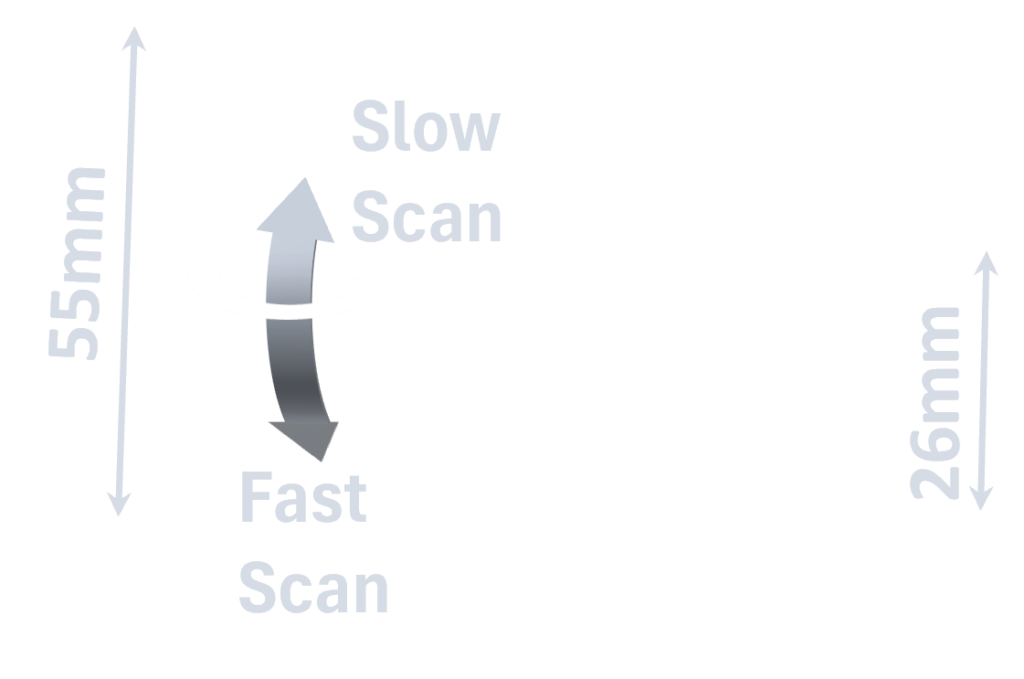

ISM 2D (hybrid) — Slow‑axis

| Parameter | Condition / Notes | ISM150 | ISM290 | Unit |

| Optical angle (H×V) | Max combined field (from flyer) | 120 × 30 | 80 × 20 | ° |

| Slow‑axis optical angle | Quasi‑static range (flyer slow‑axis row) | 120 (typ) / 120 (max) | 60 (typ) / 120 (max) | ° |

| Angle detection accuracy | Hall‑effect sensing | 0.024 (typ) | 0.024 (typ) | ° |

Notes: Slow‑axis control accuracy and additional electrical details can be shared under NDA. Final performance is application‑dependent (optics, drive, environment). Most parameters, including angle, aperture, coatings, and sensing, are customizable.

inSync Mirror–Powered LiDAR Architectures

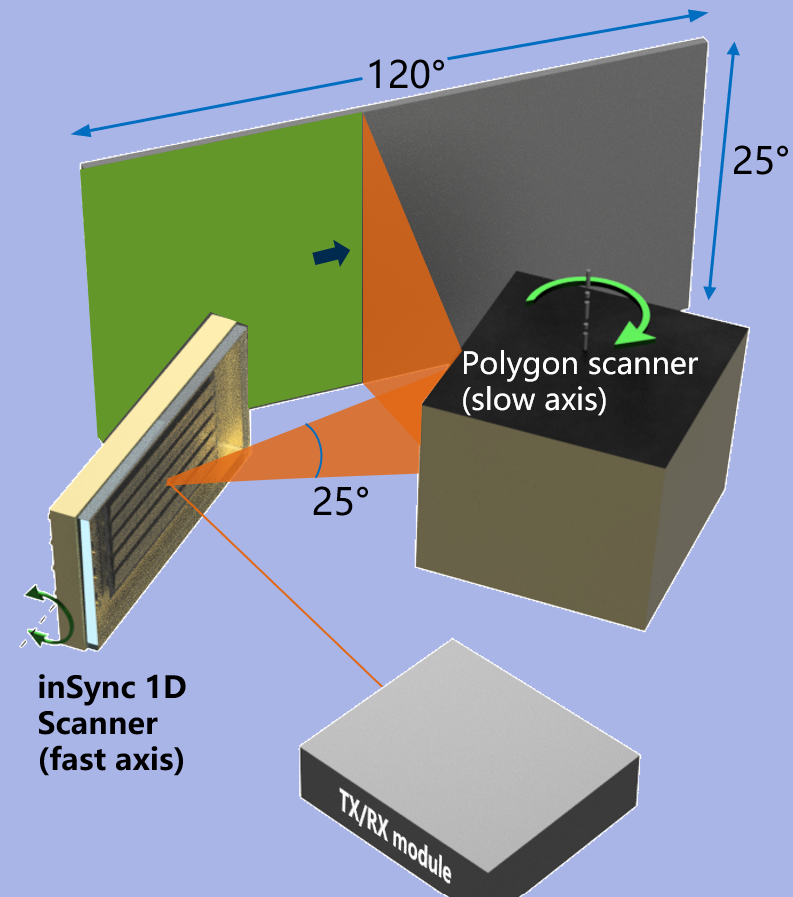

A compact engine places the hybrid 2D ISM directly in front of the TX/RX module so the resonant fast axis and quasi‑static slow axis define the field of view without bulky relay optics.

For the transmitter, an edge‑emitting laser diode with the fast axis oriented vertically and minimal vertical divergence helps maintain tight elevation control, while a few degrees of horizontal divergence simultaneously illuminates only the region later read by a SiPM array. The small illumination area, combined with true 2D scanning, suppresses ghost effects (bright‑object reflections triggering neighboring detector pixels) far better than 1D laser‑bar “flash” or 2D flood‑illumination setups.

On the receiver, a horizontally oriented detector array captures multiple points from a single pulse as the horizontal scan progresses, increasing effective line density and overall point‑cloud density.

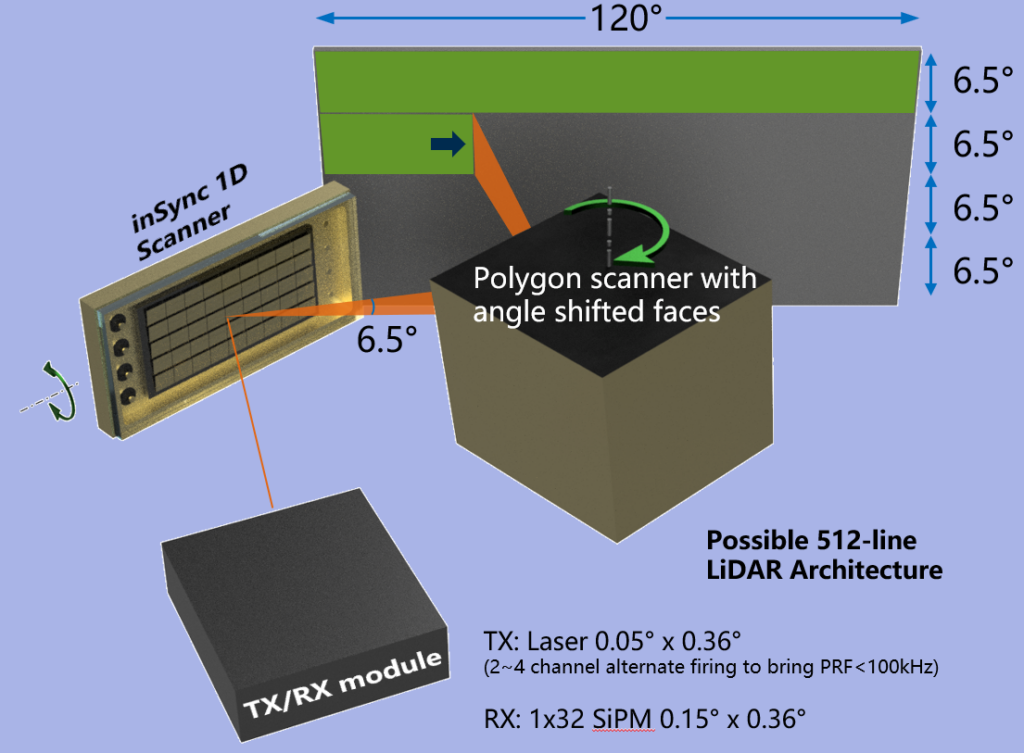

As a concrete example (right-side illustration), a 256‑line LiDAR can use a TX beam of ≈0.1° × 3.4° and a 1×32 SiPM array on RX to sample multiple horizontal spots per pulse, subject to optics and timing budget. Here ISM 1D is paired with a polygon scanner to form a 2D system when that better suits mechanics or cost.

The use of inSync 1D MEMS scanner is versatile: you can even combine it with a polygon scanner with differently angled faces and get incredibly high-resolution LiDAR systems.

Using the design depicted in the right-side illustration, you have the capability to assemble LiDAR systems with 512 lines of resolution or more.

Integration notes

The 1D scanner can serve as a fast axis or as a stand‑alone positioning/scanning mirror.

The 2D hybrid pairs the resonant fast axis with a quasi‑static slow axis for framing; it can sit directly in front of a TX/RX module for compact LiDAR engines.

We can provide application notes on TX/RX geometry, divergence choices, and reference designs upon request.

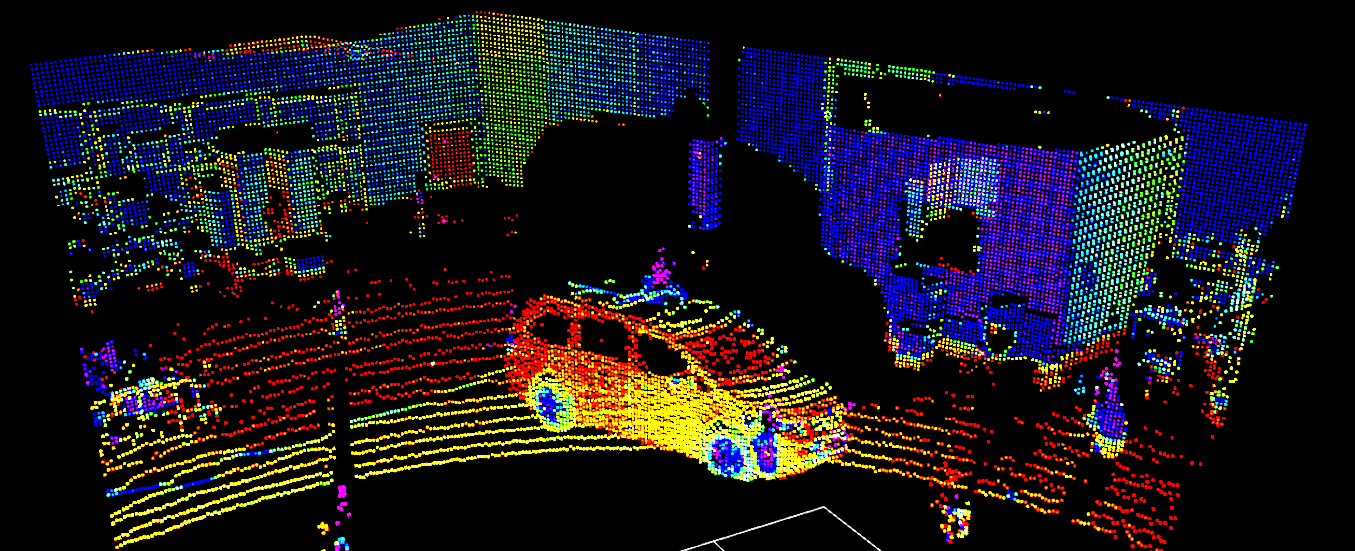

Reference LiDAR Design

The large aperture allows LiDAR to see further and clearer. As a demo, a reference LiDAR design with our MEMS scanning mirror can achieve resolution equivalent to a 250-line mechanical LiDAR with 200m effective range.