Large-Aperture MEMS Mirrors

for LBS, OCS, and LiDAR

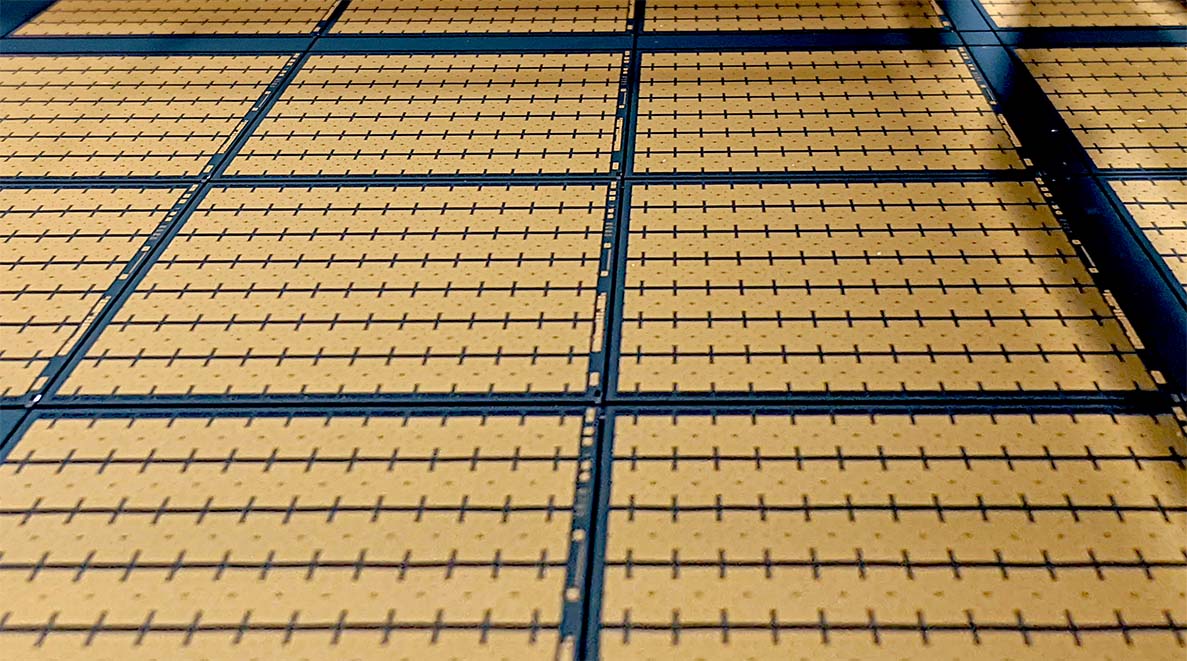

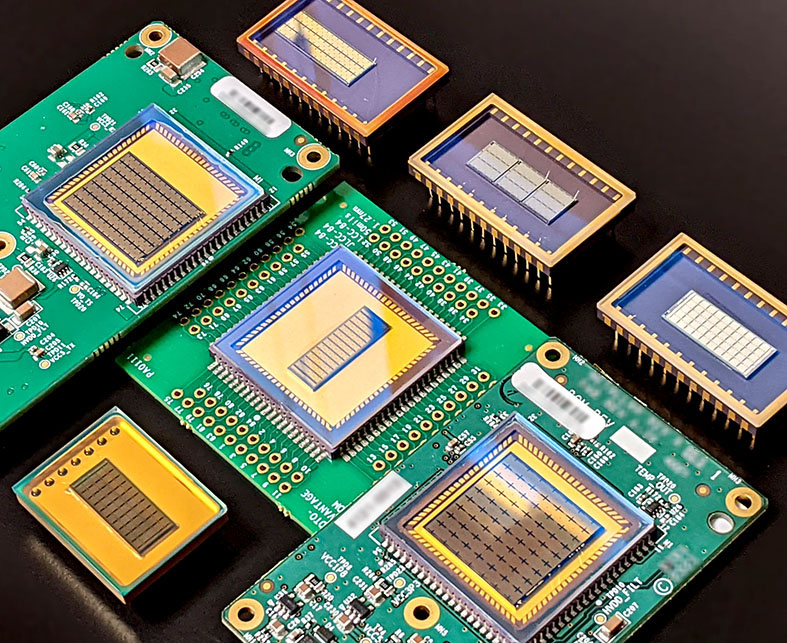

Our patented Synchronization Technology couples many tiny mirrors into a single large effective aperture—delivering stability and reliability that monolithic designs struggle to match.

QSM-2D — Quasi-Static for OCS

Two-axis quasi-static control using four synchronized comb-actuator groups—improved reliability, vibration robustness, and fast settling for optical circuit switching.

See details.

IFM — Imaging/Display (LBS)

Synchronized mirrors with a large effective aperture—stable patterns at display refresh rates and compatibility with high-brightness multi-mode laser diodes.

See details.

QSM-1D — Quasi-Static Positioning

Hold-still beam steering with fast step/settle and repeatable pointing; scalable to larger apertures.

See details.

ISM — LiDAR and General Scanning

Large-aperture resonant scanners for fixed-frequency scanning and sensing. Tested to automotive-style regimes (shock, vibration, temperature, humidity… See our technology).

See details.

• Foundry Standard Process

• Automotive-grade reliability

• Support Customization