Technology

Overview

Our approach scales optical aperture and stability by keeping individual MEMS elements small and robust, then synchronizing their motion so the array behaves as a single, large effective mirror or as a high‑force, low‑voltage actuator network.

This page summarizes published work and ongoing R&D at a high level. Detailed schematics and claims are shared under NDA.

Synchronized mirror elements

Related patents: US 11,300,776 B2; US 10,908,409 B2.

Traditional large, single mirrors become fragile and power‑hungry as aperture grows. We instead use many equal‑size mirror elements and a coupling structure that links them at matched leverage points. When one mirror rotates, the coupling transmits the motion so all mirrors rotate by the same angle.

Smaller mirrors reduce inertia and improve shock resistance. Multiple hinges and anchors spread heat into the substrate. Equal‑angle motion preserves scan geometry and simplifies control. The net effect is a large effective aperture without the reliability penalties of a monolith mirror.

Non‑linear springs to unify motion

Related patents: US 11,085,995 B2; US 11,061,201 B2.

Even with synchronized mirrors, tiny device‑to‑device variations still cause tiny angle variations. Non‑linear spring elements and limiters create a preferential operating band where mirrors settle into the same dynamic state. By shaping the torque–angle curve and using well‑placed stops, the array naturally stays in a unified motion even if perturbed.

The result is more consistent amplitude and phase across elements under environmental and manufacturing variation, improving uniformity and reducing calibration burden.

Coupled and synchronized actuator arrays

Related patents pending.

For quasi‑static steering and hold‑still positioning, we synchronize actuators rather than mirror units. Groups of comb‑drive actuators are mechanically coupled along and across axes so their forces add while unwanted degrees of freedom are strongly suppressed.

The architecture supports low drive voltage with high available torque. Coupling networks raise stiffness against lateral and out‑of‑plane disturbances, improving crash margins and reducing drift.

Because the actuator array and mirror array are distinct, their sizes can differ. Several actuator units can drive one mirror element. Multiple smaller mirrors reduce inertia and enable faster settling and higher robustness; a monolithic mirror driven by the actuator array is also possible when the application requires it.

Video (right): Each mirror in the array is driven by a group of eight synchronized comb actuators. Apparent color differences arise from diffraction—each comb acts like a tiny optical grating—and the tilt changes which wavelengths are directed toward the camera (similar to a CD or bird feathers).

Reliability

Reliability in MEMS is dominated by size and inertia; smaller moving elements tolerate shock and vibration far better than large monoliths.

Our architecture keeps each mirror element compact and lightweight, then synchronizes their motion so the array behaves like a single large aperture without inheriting the fragility of a single large part.

In vibration exposure (e.g., around 4 g RMS on a shaker, lower left video clip), reflected beam spots remain steady, indicating low sensitivity to environmental disturbance of the mirror array.

In shock testing to ~1500 g half‑sine, 3 stroke each in ±x, ±y, ±z directions (upper right video clip), devices remain mechanically intact and functional.

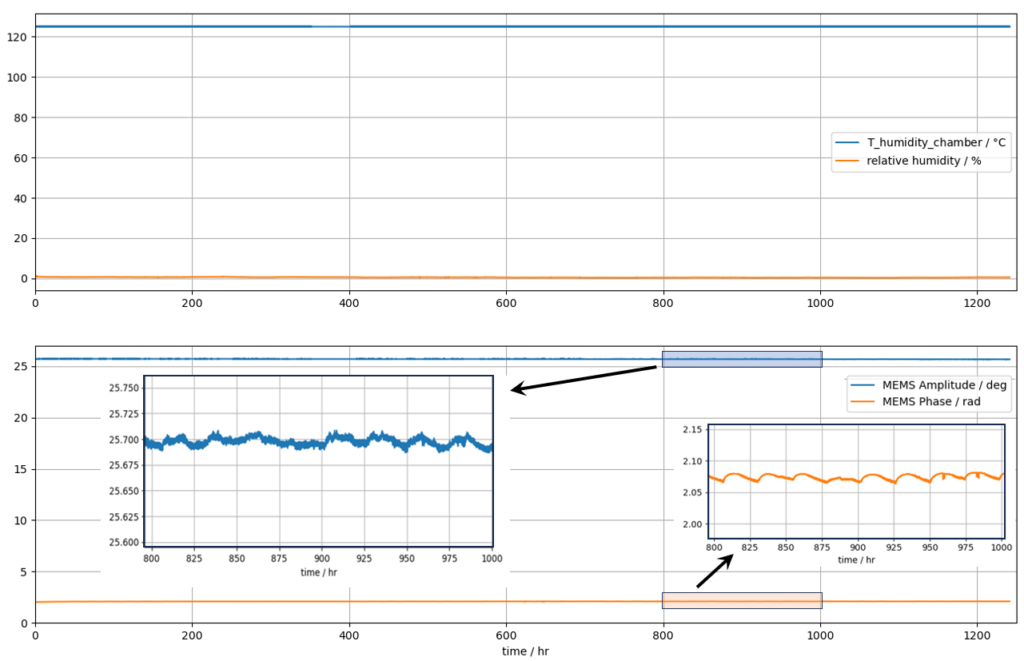

With device in operation, we test to automotive‑style regimes including pothole shock (GMW3172), random vibration (ISO‑16750‑3), temperature cycling −40 °C to 125 °C (1000 cycles), high temperature/humidity 85 °C/85% RH (1000 h), and high temperature 125 °C (2000 h, see figure below).

These outcomes flow directly from the technology above: small moving masses, multiple heat paths through hinges and anchors, and coupling that enforces equal‑angle motion.

What this enables across products

Resonant scanners with large effective apertures for displays and sensing.

Quasi‑static scanners with deterministic angles, fast settling, and low voltage for optical switching and precision positioning.

Array‑level thermal paths and small moving masses that support high reliability in real environments.

See IFM for resonant, synchronized‑mirror displays. See QSM-1D and QSM-2D for quasi‑static, synchronized‑actuator steering. See ISM for large aperture high-reliability resonant scanners.

Contact us to discuss your operating band, aperture, coatings, and control interface requirements under NDA.