QSM 2D - for Optical Circuitry Switching

Status: Early prototype (specs under development; detailed data available under NDA).

Two‑axis quasi‑static beam steering using synchronized comb actuators to deliver high force at low drive voltage with precise, deterministic positioning.

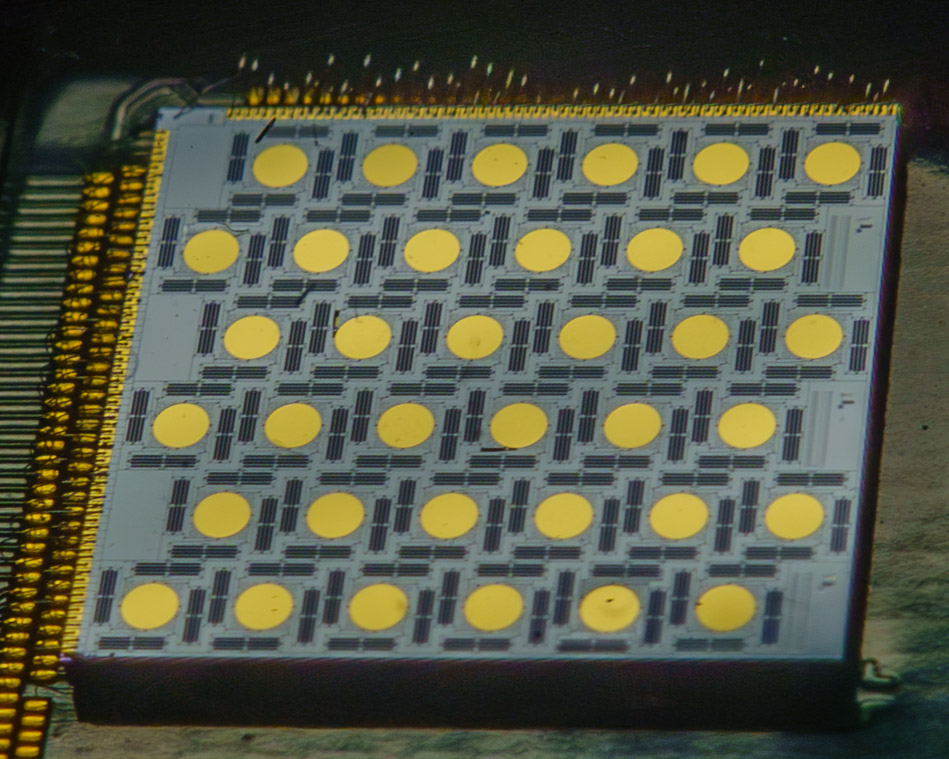

We are currently working on a 144-mirror array; The picture above shows a quarter of the array. The die is designed this way to allow quick prototyping.

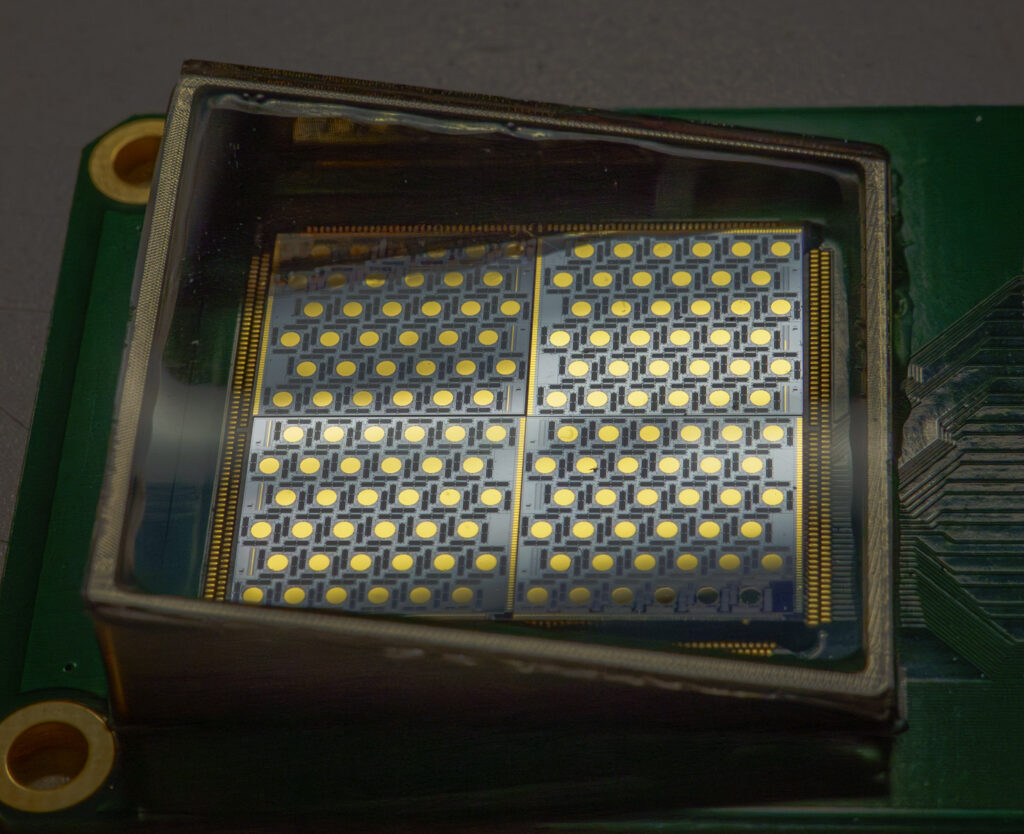

The 144-mirror array is still under development; the picture above shows the concept by placing four quarters together in a package designed for 144-mirrors.

A short history of optical switching

Optical fabrics began with mechanical fiber selectors and early MEMS micromirror cross‑connects, while integrated devices (thermo‑optic, electro‑optic) pursued chip‑scale switching. Large‑port OXC trials demonstrated the value of all‑optical reconfiguration, but deployment was constrained by size, cost, control complexity, and long‑term stability.

With modern data‑center traffic growth, coherent optics, and leaf‑spine fabrics, there is renewed demand for scalable, low‑loss, protocol‑agnostic optical switching.

Industry adoption (public information)

At hyperscale, Google has publicly described large‑scale optical circuit switching in production datacenter networks and ML clusters. Reported outcomes include roughly 30% capex reduction and ~41% power reduction at the fabric level, enabled by replacing the spine with MEMS‑based OCS and using SDN to reconfigure direct‑connect topologies. These reconfigurable lightwave fabrics support very large ML superpods and Jupiter‑class deployments.

Key challenges for today's OCS

Optical switches based on 2D MEMS mirrors are conceptually straightforward, yet large‑scale implementation remains challenging. From the MEMS and system perspective, the constraints include:

- Yield and uniformity across 2D arrays of quasi‑static mirrors;

- Fast response with tight control accuracy;

- Reasonable low drive voltage targets;

- Low drift over time and temperature;

- Low sensitivity to environmental vibration (otherwise vibration isolation adds system complexity, such as thermal and wiring).

Many actuation mechanisms—thermal, electromagnetic, piezoelectric—struggle to meet the combined requirements of low drift, low power, fast settling, and high repeatability at scale. Even with low intrinsic drift, practical systems still need high‑speed angle sensing and closed‑loop control on each mirror to ensure repeatable port‑to‑port alignment.

inSync’s QSM‑2D with synchronized comb actuators

In the clip, a large beam-diameter red laser is directed onto a 36-mirror array. The 36 individual beams reflected by the mirror array are projected onto a paper screen placed above the device, so you can see the steering response directly as the bright spot moves on the paper.

In the first segment, the mirror executes two‑axis quasi‑static moves: precise tilts on X and Y that translate to controlled spot motion and stable holds on the screen. This illustrates the deterministic positioning and fast settling targeted for OCS port‑to‑port alignment.

The final segment shows elliptical motion of the mirrors. Each mirror is given a different long/short axis and angular speed. Mist is provided to facilitate the visualization of individual reflected laser beams.

QSM‑2D uses coupled (synchronized) comb‑drive actuator groups on each axis to sum force and stiffness while maintaining fine analog control. The mirror is held quasi‑statically with precise, deterministic two‑axis steering at low voltage.

What this means at the MEMS level

Low‑voltage operation: < 85 Vpp

High available force reduces driver complexity and eases isolation constraints;

Actuators combined in parallel increase stage stiffness and suppress drift;

A gimbal‑less, lightweight mirror—driven by a high‑force, high‑stiffness stage—improves shock and vibration robustness;

Robust mechanics also simplify fabrication and handling at the wafer level, supporting automated processing and high yield;

High stiffness and force enable fast response. For example, a 0.8 mm mirror can reach ~90% of a step in roughly 90 µs (estimation based on 3 kHz resonance frequency), and larger apertures (e.g., ~1.6 mm as shown in the demo video) remain practical with proportionally adjusted response (e.g., ~1.4 kHz resonance).

What this means for an OCS fabric

Deterministic port‑to‑port states with fast settling and excellent pointing repeatability translate to stable, low‑loss connections. A larger mirror aperture with simple metallic coatings supports low insertion loss and broadband, protocol‑agnostic operation compatible with WDM systems. Low‑voltage, efficient actuation reduces rack‑level power. Distributed actuation and small moving masses promote high reliability and serviceable calibration over time.

Technical details from the in‑progress patent are intentionally omitted here; additional information can be shared under NDA when available.

Customizable options

- Aperture and clear‑aperture geometry;

- Two‑axis tilt range;

- Settling behavior and hold stability;

- Mirror coatings for target bands (e.g., C/L‑band or visible);

- Package style and alignment strategy;

- Monitoring and control interface options.